Hydraulic Scissor Lift Tables |

EnKon Hydraulic Scissor Lift Tables are designed and built based on countless hours of knowledge from industrial applications. When your industrial application has specific requirements for lift table performance — size, capacity, speed, duty cycle, safety features, clean room needs and other concerns — Enkon can build the scissor lift that meets your needs. Safety Features are incorporated into the Enkon Hydraulic Scissor Lift Tables. Enkon offers, as standard or optional, the following features: safety maintenance stop, safety velocity fuse, emergency stop switch, pilot operated check valve, pressure relief valve in pump, adjustable pressure compensated flow control valve, fully redundant secondary locking anti-fall device, upper limit switch, lower limit switch, safety toe stop, safety bellows skirting. Other features include items such as one touch controls, multiple position automated controls and controls for explosion-proof. Clean and Green Low Profile – Better Operator Performance High Strength – Low Maintenance Timely Delivery A Michigan-Based Company |

|

|

|

Standard Product: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section 2 |

|

Description: The formed top frame offers a powerful rectangular platform in three sizes, from 19” wide by 55” long to 21” wide by 95” long, with two hydraulic cylinders providing stable and powerful lifting for high capacity applications.

|

|

|

|

|

|

|

|

|

|

Section 3 |

|

Description: The LSH05 supports a large variety of manufacturing applications, and are popular with companies that need a large quantity of lifts to use in mass production.

|

|

|

|

|

|

|

|

|

|

Section 4 |

|

Description: A reliable lift for general industry applications, the LSH01 utilizes captured wheel tracks on both the platform and the base, which provide strong, stable support for applications that might employ offset loading on occasion.

|

|

|

|

|

|

|

|

|

|

Section 5 |

|

Description: A very functional workhorse lift that integrates easily with AGC and AGV systems, the LSH16 is extremely stable, with the capability of lifting up to 6000 lbs.

|

|

|

|

|

|

|

|

|

|

Section 6 |

|

Description: Employing extremely strong scissors that can handle offset loading, the LSH07 is frequently used in operator, platform lifts, lifting vehicles and robotic operations, sometimes placed side by side to address large load requirements.

|

|

|

|

|

|

|

|

|

|

Section 7 |

|

Description: A stable, high rise lift, the LSH15 is used in a number of military applications.

|

|

|

|

|

|

|

|

|

|

Section 8 |

|

Description: The ratchet takes all the load, supported by lightweight tubal scissors and captured wheel guides, enabling the LSH14 to provide safe and stable high travel.

|

|

|

|

|

|

|

|

|

|

Section 9 |

|

Description: Often used on loading docks and even power plants, the LSH10 marries low profile with hydraulic post power.

|

|

|

|

|

|

|

|

|

|

Section 10 |

|

Description: Originally designed to support the installation of heavy electric car batteries, the LSH06 provides stable lifting that resists side to side motion.

|

|

|

|

|

|

|

|

|

|

Section 11 |

|

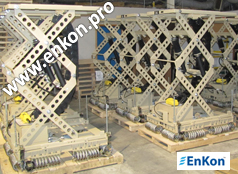

Description: Solid engineering and heavy duty steel enable strong, stable and dependable lifting of heavy loads to great heights. Designed for military applications, this lift system can be used whenever safety and stability are needed.

|

|

|

|

|

|

|

|

|

|

Section 12 |

|

Description: Two or three cylinders support the powerful scissors that provide solid, stable lifting of up to 10,000 pounds to great heights. This powerful lift is the foundation of several lift combinations that provide incredible lifting power and raised heights.

|

|

|

|

|

|

|

|

|

|

Section 13 |

|

Description: Originally designed for use in an engine block casting facility, this lift can raise 1000 to 10,000 lbs. easily, and can provide millions of cycles in its lifetime.

|

|

|

|

|

|

|

|

|

|

Section 14 |

|

Description: The LSH18 can be used in a wide variety of heavy duty lifting applications requiring high capacities, and large platform dimensions. An optional upgraded bearing package can also be paired with this lift to ensure an easy bolt-on hub bearing replacement, and a long lift life.

|

|

|

|

|

|

|

|

|

|

Section 15 |

|

Description: The LSH19 can be used in a wide variety of heavy duty lifting applications requiring high capacities, and large platform dimensions. An optional upgraded bearing package can also be paired with this lift to ensure an easy bolt-on hub bearing replacement, and a long lift life.

|

|

|

|

|

|

|

|

|

|

Section 16 |

|

Description: The LSH20 can be used in a wide variety of heavy duty lifting applications requiring very high capacities, and large platform dimensions. An optional upgraded bearing package can also be paired with this lift to ensure an easy bolt-on hub bearing replacement, and a long lift life.

|

|

|

|

|

|

|

|

|

|

Section 17 |

|

Description: Used in a variety of applications, the LSH17 was originally designed for military applications that required the ability raise a light capacity to high height without compromising stability.

|

|

|

|

|

|

|

|

|

|

Section 18 |

|

Description: Incorporating a bearing package commonly used in belt drive and ball screw systems, this lift ratchets up to great heights. The LSH11 also provides an extra-wide hub, a special pivot package, and easily replaceable bearings that enable millions of cycles.

|

| 1 |

|

|

|

| 2 |

|

|

|

| 3 |

|

|

|

| 4 |

|

|

|

| 5 |

|

|

|

| 6 |

|

|

|

| 7 |

|

|

|

| 8 |

|

|

|

| 9 |

|

|

|

| 10 |

|

|

|

| 11 |

|

|

|