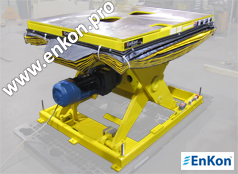

Enkon Ball Screw Scissor Lift Tables are designed and built based on countless hours of knowledge from industrial applications. When your industrial application has specific requirements for lift table performance — size, capacity, speed, duty cycle, safety features, clean room needs and other concerns — Enkon can build the scissor lift that meets your needs.

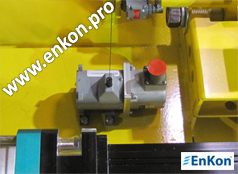

Safety Features are incorporated into the Enkon Ball Screw Scissor Lift Tables. Enkon offers, as standard or optional, the following features: fully redundant secondary anti-fall locking device, fast acting normally locked motor brake, anti-fall ball screw catch nut system, safety maintenance stop, emergency stop switch, upper limit switch, upper over travel limit switch, lower limit switch, lower over travel limit switch, safety toe stop, safety bellows skirting . Other features include items such as one touch controls, multiple position automated controls and controls for explosion-proof.

Clean and Green

Enkon Ball Screw operator scissor lift tables are 100% electric powered used for advance automation technology applications.

High Programmability – Better Automated Performance

The Enkon scissor lift tables accommodates advance automation applications by accurately positioning product in various calculated heights, giving advance robotic technology repeatable accuracy and precision control. Enkon electric lifts are programmed to raise loads as fast as 12 in/sec or as slow as .03 in/sec for precise applications.

High Strength – Low Maintenance

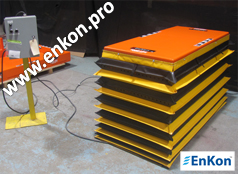

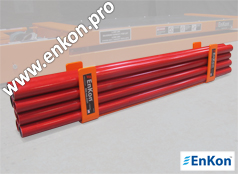

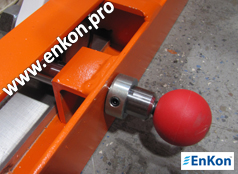

Enkon Ball Screw Scissor Lift Tables are designed with quality, high strength, steel to meet safety factors required for heavy automated industry applications. Manufactured with internal or external electric motor systems provided in either AC or DC voltage. Each self-lubricating pivot point moves fluently on PTFE (polytetrafluoroethylene) bearings resulting in the ability to run high duty cycles or grease fittings can easily be added to meet customer requirements. Enkon lubricating canisters provide ball screws with a continuous supply of grease. These design features are a standard part of our scissor lift tables to provide a product to run for millions of cycles to increase the mean time to repair (MTTR). Enkon ball screw scissor lift tables have a lifting capacity of up to 60,000 lbs. Enkon ball screw scissor lift tables are easily customized and integrated into advance automation, automated guided vehicles and automated guided carts (AGV's and AGC's), robotics, conveyors, skillet systems, machine builders, workstations and production assembly lines.

Timely Delivery

Enkon manufactures quality lift systems which integrate our expertise with customers' needs and deadlines. As a result, we developed the Enkon Order Process, which enables customers' input throughout the process. Establishing and meeting mutually agreed-upon deadlines, and enabling communication throughout the process, means that Enkon Ball Screw Scissor Lift Tables are available to ship in a timely manner.

A Michigan-Based Company

EnKon Lifts are Proudly Designed and Manufactured in the USA